AnchoRock + KPA: Accelerating Growth in Construction

Transition your construction company to a paperless, automated system with AnchoRock + KPA. Ditch printouts and PDFs for seamless certification tracking and reporting. Our intuitive dashboard streamlines task management for safety programs, compliance, and field management. Stay OSHA compliant and maintain records effortlessly, saving you valuable time each week.

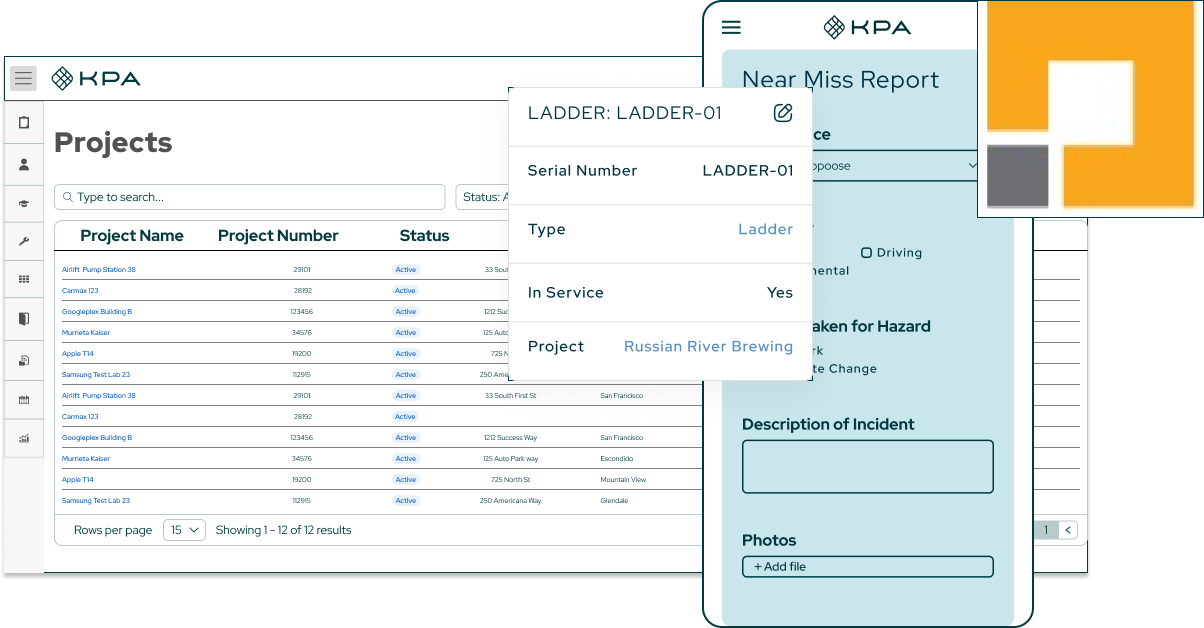

Manage Your Construction Safety Program From Anywhere

Our platform offers complete configurability, allowing you to automate daily field tasks, track compliance, and manage safety protocols efficiently. Say goodbye to paperwork and hello to streamlined operations with our innovative solution.

- Incident Management

Encourage workers to report near misses and observations of unsafe conditions or practices to proactively address potential hazards. - Job Planning

Develop and implement job hazard analyses (JHA), job safety analyses (JSA), activity hazard analysis (AHA), and pre-task plans to assess risks and establish safety protocols. - Reporting & Dashboards

Manage the entire process from the first report of an incident to conducting thorough investigations to determine root causes and prevent future occurrences.

- Toolbox Talks

Facilitate safety discussions with workers before starting work shifts to address specific hazards, procedures, and best practices. - Inspections & Audits

Conduct regular inspections and audits of job sites, equipment, and vehicles to identify hazards and ensure compliance with safety regulations. - On-Site Consulting & Training

Provide on-site training to workers on safety procedures, equipment operation, and emergency response protocols.

Built for Construction Safety Professionals by Construction Safety Pros

KPA offers a mobile-first workplace safety management system for the construction industry that includes user-friendly incident management, audits and inspections, and online certification.